Core Holder

Core Holder

Stainless-Steel Hassler Type, Biaxial, or Triaxial Core Holder

Stainless-Steel Hassler Type, Biaxial, or Triaxial Core Holder

Core Holder with Customized Pressure Taps

Core Holder with Customized Pressure Taps

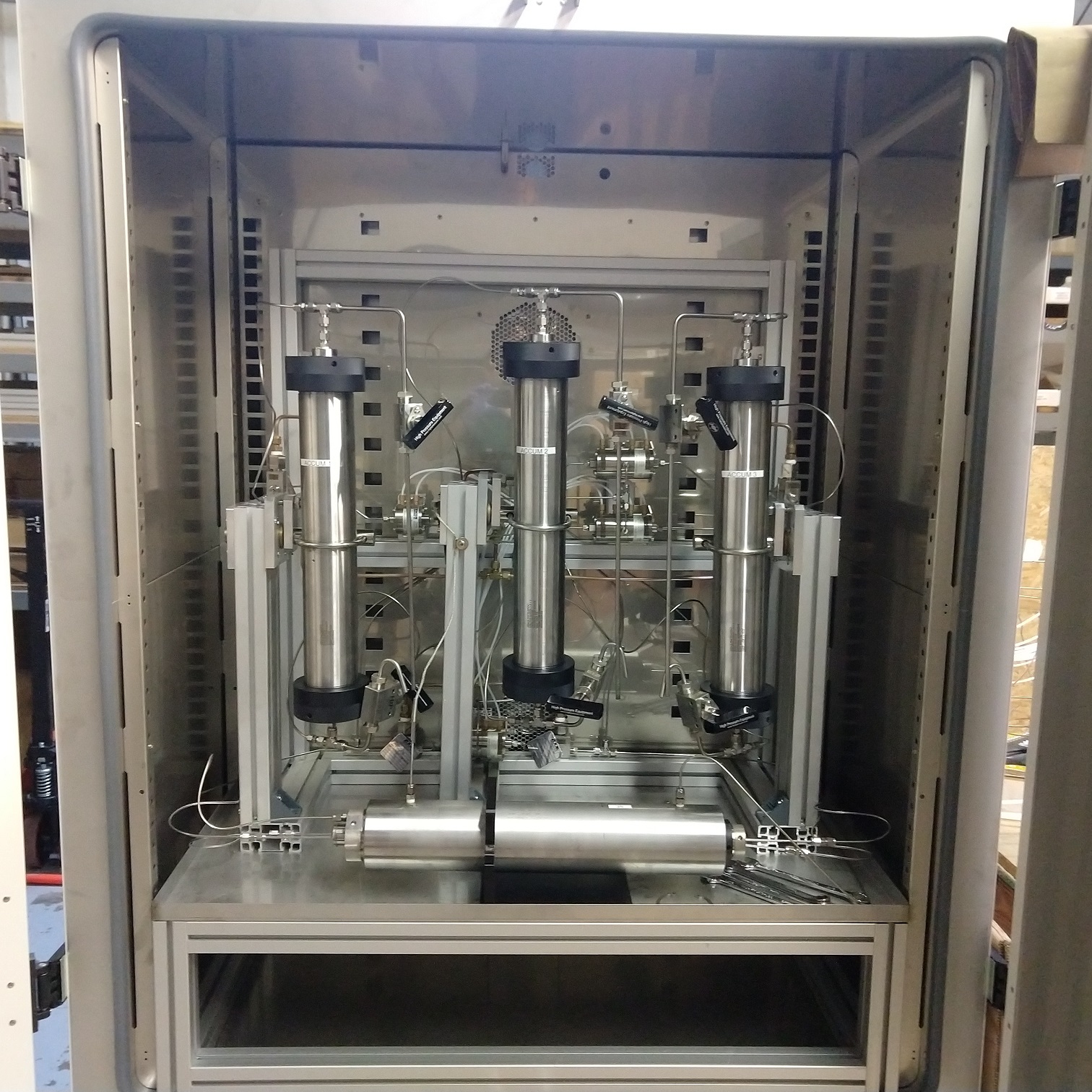

Core Holder in Oven

Core Holder in Oven

.jpg)

.jpg)

.jpg)

Standard Hassler Type, Biaxial, or Triaxial Core Holder Accurately Simulates Real-Life Fracking, Drilling, and Displacement

The Grace Instrument Core Holder is used in fluid permeability and core flow tests. There are three configurations:

- Hassler Type – a core holder with a Hassler sleeve that applies confining pressure via a pump. The confining pressure exerts radial load to the core sample, which simulates reservoir overburden pressure.

- Biaxial – a core holder that applies common radial and axial load to the core sample.

- Triaxial – a core holder that applies independent radial and axial load to the core sample.

The Grace Instrument Core Holder has many applications, like allowing researchers to easily evaluate the behavior of shale, sandstone, or other types of rock in fracking, drilling, and/or displacement scenarios. Using these results, ideal drilling or displacement methods can be engineered to extract or displace oil from rock formations.

Modular Device Compatible with Many Standard Core Flooding Systems or External Pump Attachments

The Grace Instrument Core Holder is a modular device and is conveniently compatible with many standard core flooding systems or external pump attachments:

- Grace Instrument M9100 Automatic Core Flow Tester

- Grace Instrument M9145 Porosimeter

- Grace Instrument M9170 High Pressure Porosity and Permeability System

- Grace Instrument M9175 Steady State Permeameter

- Grace Instrument M9300 Foam Loop & Core Flow Tester

- Use your own system. Any standard Hassler type, biaxial, or triaxial core flow system.

- Use your own system. Any standard Hassler type, biaxial, or triaxial external pump attachment.

Robust Stainless-Steel and Viton Construction

Robust and durable, the Grace Instrument Core Holder body is constructed from 17-4 PH stainless-steel (a material stronger than SS-316 stainless-steel)

and is non-corrosive. The core sleeve and O-rings are composed of heat-resistant, pressure-resistant Viton material.

Highly Customizable Device Accommodates Extremely High Pressure and Temperature, Wide Range of Core Sample Sizes, and Pressure Tapping

The Grace Instrument Core Holder is highly customizable. It can be custom-built to confining pressure specifications anywhere from 500 psi to 20,000 psi

and custom temperatures from -20°F (~-7°C) up to 400°F (~204°C). It can also be custom-built to accommodate core samples anywhere from 1 to 4 inches in diameter

by 3 to 12 inches in length. Spacers are available to accommodate different sample sizes within the same core holder. The pressure taps are highly

customizable—custom pressure tap spacing and valve connection configurations are available. Equispaced pressure taps at 1, 3, 4, 5, and/or 7 inches,

as well as several other configurations, are possible.

Streamlined Design Allows for Multiple Test Operations With Minimal Setup and Cleanup Between Tests

No fluid draining or disassembly is required between tests. Designed to maximize efficiency, the core holder's innovative design allows for multiple test

operations to be performed without draining fluid or disassembling the core holder, enabling the researcher to conduct multiple tests without multiple setups and/or cleanup.

Replacing core samples is quick and easy. Once pressure is released, simply unscrew two parts by hand: the tri-lock plug on one end and the screw cap on the other. Gently push one end of the sample to slide it out. Slide in a new core sample, screw the plugs back on, and you are ready to get back to testing!

All other components, such as the sleeve and caps, do not need to be adjusted at all when switching out cores.

Even though the replacement process is easy, test results remain uncompromised, with zero contamination with any other fluids.

Essential Components, Connections, Spare Parts, and Accessories are Included and/or Available

The Grace Instrument Core Holder conveniently includes essential components, connections, and useful spare parts. Accessories and additional spare parts are also available and can be ordered from Grace Instrument at any time.

Each core holder contains an inlet, outlet, and distribution plug to evenly and accurately inject fluid throughout the core sample. The durable, longlasting NPT/Angular Cone/LP fitting withstands elevated temperature and pressure.

The pressure taps are highly customizable, and custom pressure tap spacing and valve connection configurations are available. Equispaced pressure taps at 1, 3, 4, 5, and/or 7 inches, as well as several other configurations, are possible.

One replacement Viton core sleeve and some replacement Viton O-Ring gaskets are included FREE with the unit.

An optional rotating stand accessory (sold separately) is available that enables the researcher to place the core holder in horizontal, vertical, or angled positions.

Reliable, Long-Lasting Testing Device

The Grace Instrument Core Holder is a reliable, long-lasting testing device that has been successfully used by large oil and gas laboratories worldwide.

Each unit comes with a one-year warranty, and an optional extended warranty is also available.

| Condition: New |

| Core Holder Type Options: Hassler Type, Biaxial, Triaxial |

| Sleeve Type Options: Hassler Type, Biaxial, Triaxial |

| Stress Type: Radial |

Compatibility:

|

| Core Holder Body Material: Non-Corrosive 17-4 PH Stainless Steel |

| Core Sleeve Material: Viton or Aflas |

| O-Ring Gasket Material: Viton |

| Wetted Material: 316 SS or Hastelloy C-276 |

| Confining Pressure Range: Highly customizable. Can be custom built anywhere from 500 psi to 20,000 psi. |

| Temperature: Highly customizable. Can be custom built anywhere from -20°F (~-7°C) up to 400°F (~204°C). |

| Core Sample Size: Highly customizable. Can be custom built anywhere from 1 to 4 inches in diameter by 3 to 12 inches in length. Spacers are also available to accommodate different sample sizes within the same core holder. |

| Fitting Type: NPT/Angular Cone/LP |

| Pressure Tap Spacing: Highly customizable. Equispaced pressure taps at 1, 3, 4, 5, and/or 7 inches, as well as several other configurations, are possible. |

| Valve Connection Configurations: Highly customizable. Equispaced pressure taps at 1, 3, 4, 5, and/or 7 inches, as well as several other configurations, are possible. |

| Included Replacement Parts: One Viton Core Sleeve (Additional Sold Separately), Some Replacement Viton O-Ring Gaskets (Additional Sold Separately), Spacers |

| Accessories (Optional) (Sold Separately): Rotating Stand (Vertical, Horizontal, and/or Angled Positions) |

| Warranty: 1-Year Warranty (Optional extended warranty available.) |

- Ideal for fluid permeability and core flooding testing.

- Standard Hassler type, biaxial, or triaxial core holder configurations available.

- Exerts radial stress.

- Highly customizable. Can be custom built for extremely high pressures (500 psi to 20,000 psi), high temperatures (-20°F (~-7°C) up to 400°F (~204°C)), and a wide range of core sample sizes.

- Pressure tap spacing and valve connections are highly customizable (equispaced pressure taps at 1, 3, 4, 5, and/or 7 inches and many other configurations possible).

- Modular device compatible with standard core flooding systems or external pump attachments.

- Reliable, long-lasting testing device used in labs worldwide.

- Robust stainless-steel (optional Hastelloy) and Viton construction.

- Streamlined design allows for minimal setup and cleanup between tests.

- Replacing core samples is quick and easy. No fluid draining or disassembly is required between tests.

- Essential components, connections, spare parts, and accessories are included and/or available.

- Inlet, outlet, and distribution plug evenly and accurately inject fluid throughout samples.

- Durable NPT/Angular Cone/LP fitting withstands elevated temperature and pressure.

- Optional rotating stand accessory allows core holder to be placed in horizontal, vertical, or angled positions.

- One replacement Viton core sleeve and some replacement Viton O-Ring gaskets included FREE with each unit.

- Additional spare parts available and can be ordered at any time.

- One-year warranty included with each unit. Optional extended warranties available.

- Grace Instrument is an ISO 9001:2015 certified company.