Drilling Simulator

M2200 HPHT Lubricity (Tribology), Dynamic Filtration, & Drilling Simulator

- Height: 27.5 in.

- Width: 18 in.

- Depth: 21 in.

- Weight: 250 lbs.

- Max Pressure: 2,000 psi | Max Temp: 500°F (260°C)

- U.S. Patent: 9,194,784

- U.S. Patent: 10,215,001

HPHT Lubricity, Filtration, & Drilling Simulation Multifunction Tester

The M2200 HPHT Lubricity (Tribology), Dynamic Filtration, and Drilling Simulator

provides multiple test functions in one compact unit, offering a computer controlled

test environment which can realistically simulate high pressure

high temperature downhole conditions while allowing the user to perform

multiple test functions, saving money, training and research time, and the

laboratory space that multiple test devices would otherwise require.

The M2200 is fully compliant with API 13.

Real HPHT Dynamic Lubricity Testing

The M2200’s very repetitive COF (coefficient of friction) measurement of plus or minus 0.01 is due to its unique, patented design.

The M2200 is the only HPHT lubricity (tribology) tester available in the USA that is reliable in evaluating

dynamic lubricity performance on different types of drilling fluids, and can do so at high pressure

and high temperature reservoir conditions that are completely user-controlled. The M2200 can evaluate

all oil-based drilling fluids, water-based drilling fluids, and synthetic-based drilling fluids.

Additionally, chemical additives can be blended into the drilling fluid to evaluate the change in the lubricity performance.

Dynamic HPHT Filtration Test

The M2200 includes a pressurized, temperature-controlled

environment containing a filtrate medium which realistically

simulates a downhole well bore.

When the simulation chamber is filled with drilling fluid under either

static condition or re-circulation condition, a shear bob simulates

the drilling string centrally or off-centrally rotating inside of the

filtrate medium to produce a shear inside of the filtrate medium. The

filter cake deposit becomes visible on the interior of the filtrate

medium as the fluid is sheared, and the resulting build-up can be

examined following the completion of the test. An optional mud

circulation pump is available at reduced temperature and pressure

conditions.

Differential Sticking Test

A differential sticking test can be performed whereafter the filter cake

has been deposited, the load is applied and then the rubbing shoe is

rotated. The torque required to move the rubbing shoe is measured.

Particle Plugging Test

Lost circulation is the uncontrolled flow of whole drilling fluid into a

formation with no return to surface, especially within those

formations that are inherently fractured, cavernous, or have high

permeability. Lost circulation also occurs when improper drilling

operations damage the mud cake as drilling fluid invades and

further damages the formation.

The M2200 includes a specialized filtrate medium with an artificial

fissure that can be used to perform particle plugging tests, which

determine the effectiveness of additives to help prevent lost

circulation in the filtrate medium. Particle plugging tests also

determine the effectiveness of bridging materials. M2200 simulates

an off-centric drilling string rotating and damaging the filter cake,

and thus, measures the performance of bridging materials on

improvement of fluid loss.

Real HPHT Drilling Simulation System

The M2200 can be also used to simulate drilling operations

and optimize mud systems to reduce overall drilling costs.

The M2200 hardware includes an ultra-realistic well-bore

simulation chamber, which allows the user to test the

penetration rate on actual core samples using a real drill bit.

The core sample options can be different types, such as

sandstone, limestone, ceramic, etc., allowing the user to select

for the matching rock parameters of the reservoir to be drilled.

The penetration rate is measured through linear transducers.

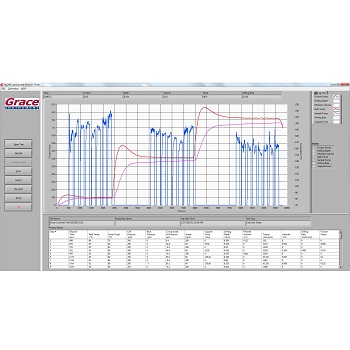

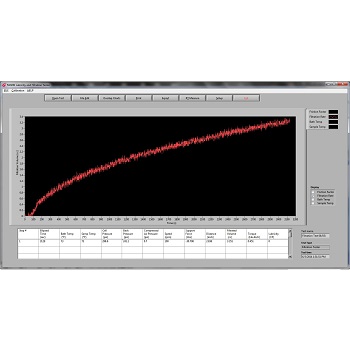

The pressure and temperature of the simulation chamber are

controlled by custom M2200 PC software, which monitors and

records test results in real time. Filtration during the drilling

process is measured and recorded as well.

The instrument also includes custom software called

M2200 PC, which gives the user the ability to create test

sequences with multiple testing parameters.

| U.S. Patent Numbers: 9,194,784 and 10,215,001 | |||

| Dimensions: 27.5" H x 18" W x 21" D | |||

| Weight: 250 lbs. | |||

| Temperature Range: Amb. to 500 °F (260°C) | |||

| Working Pressure: 2,000 psi | |||

| Max Load (Normal) Force: 600 lb | |||

| Voltage: 220-240V AC at 50-60 Hz | |||

| Frequency: 50-60 Hz | |||

| Power: 1,200 W | |||

| Sample Volume: 350 ml | |||

| Max Filtrate Volume: 45 ml | |||

| Shear Bob Speed: 0 to 600 rpm | |||

| Compliance Standards: Fully Compliant with API 13B | |||

| Lubricity/Differential Sticking Tester |

Dynamic HPHT Filtration Tester |

Particle Plugging Tester |

Real HPHT Drilling Simulator |

| Max Torque: 120 lb./in. (14 N.m) |

Max Differential Pressure: Determined by Core Strength |

Max Differential Pressure: Determined by Core Strength |

Max Differential Pressure: 500+ psi (Or Determined by Core Strength) |

| Coefficient of Friction (COF) Accuracy: ± 0.01 (Particle fluids may experience high errors.) |

-- | -- | Max Torque: 120 lb./in. (14 N.m) |

| -- | -- | -- | Max Penetration Depth: 1 inch |

| -- | -- | -- | True measurement of rate of penetration (ROP). |

- The M2200’s very repetitive COF (coefficient of friction) measurement of ±0.01 is due to its unique, patented design.

- Newly designed cell cap is interchangeable with older cells.

- Heating jacket can be locked at 30° inclined angle for the easy installation and extraction of test cell.

- Programmable temperature controller increases the cell temperature at desired rate.

- The M2200’s unique design allows it to equip a rubber wiper that can intentionally damage/wipe mud cake off the filtration element. This simulates the high angle drilling situation of a drill pipe sitting on the bottom of a well hole.

- The M2200 can simulate both concentric and off-centric location of drilling pipe off the drill hole.

- Apparatus is in accordance with API Recommended Practice 10B-2.

- Fully compliant with API 13B.

- Includes custom M2200 PC software.

Downloads for the M2200 Lubricity Dynamic Filtration Drilling Simulator:

Read more about our instrument's technical applications within these scientific and academic publications:

-

Nafta-Gaz, 2023, R. 79 No. 3, 157-170 2023

Drilling mud based on synthetic polymers with the addition of nanomaterials adapted to borehole conditions

Filtration of cores with a porosity of 20 μm were performed with a Grace M2200 Lubricity Tester.

https://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-299fde88-2236-424e-b9cc-9a9834b57a78?q=bwmeta1.element.baztech-dabc15aa-0811-42ff-85d7-002a9bbc6808;1&qt=CHILDREN-STATELESS

-

Nafta-Gaz, 2023, R. 79 No. 3, 171-183 2023

Influence of washing liquids on the quality of cementing pipes after using drilling muds with different hydration inhibition mechanisms

A Grace M2200 Lubricity Tester was used to produce mud sludge under hole-like conditions.

https://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-f2f65e6e-845a-48a3-968c-a7faaed177b4

-

Nafta-Gaz 2022, nr 5, s. 375-385 2022

Polymers, synthetic, for regulating the filtration of drilling muds under elevated temperature conditions

Dynamic filtration results from synthetic polymers used to regulate drilling fluids were measured using a Grace M2200 Lubricity Tester.

https://www.inig.pl/magazyn/nafta-gaz/Nafta-Gaz_2022-05-05.pdf

-

Nafta-Gaz 2019, nr 5, s. 275-282 2019

Possibilities of improving the lubricity properties of drilling muds used in industrial conditions

Dynamic fluid invasion experiments were conducted using the M2200 drilling simulator. Effectiveness tests of four lubricants in drilling fluids were tested using a Grace 2200 Lubricity Tester.

https://www.inig.pl/magazyn/nafta-gaz/Nafta-Gaz_2019-05_5.pdf

-

Journal of Petroleum Exploration and Production Technology, March 2019, Volume 9, Issue 1, 281-296 2019

Smart Lost Circulation Materials for Productive Zones

Dynamic fluid invasion experiments were conducted using the M2200 drilling simulator.

https://link.springer.com/article/10.1007%2Fs13202-018-0458-z

-

Journal of Energy Resources Technology, January 2019, Volume 141, Issue 7 2019

A Holistic Approach to Characterize Mud Loss Using Dynamic Mud Filtration Data

The dynamic mud filtration experiments were performed using the M2200 drilling simulator.

http://energyresources.asmedigitalcollection.asme.org/article.aspx?articleid=2719407

-

ARMA-2018-544 2018

Pore-Scale Mud Invasion in Different Rock Samples and Wellbore Conditions: Implications for Lithology Dependent Wellbore Strengthening

M2200 drilling simulator was used to perform the dynamic-radial mud invasion experiments.

https://onepetro.org/conference-paper/ARMA-2018-544

-

SPE-189596-MS 2018

A New Approach to Characterize Dynamic Drilling Fluids Invasion Profiles in Application to Near-Wellbore Strengthening Effect

Dynamic fluid invasion experiments were conducted using the M2200 drilling simulator.

https://onepetro.org/conference-paper/SPE-189596-MS

-

SPE-189509-MS 2018

Integrated Image Processing and Computational Techniques to Characterize Formation Damage

Dynamic fluid invasion experiments were conducted using the M2200 drilling simulator. The advantage of using this approach is that it simulates drill pipe rotation with drilling mud inside the inner diameter of a core.

https://onepetro.org/conference-paper/SPE-189509-MS

-

SPE-189471 2018

Investigating Impact of Rock Type and Lithology on Mud Invasion and Formation Damage

Characterizing water based mud’s invasion and damage to different rock cores representing various lithologies, under simulated dynamic wellbore condition. M2200 has been used to simulate dynamic wellbore condition as a drilling simulator, capable of rotating a shaft that is centered between the inner diameter of the damaged porous media. Using this approach, the formation damage profile of WBM on different lithologies was investigated.

https://onepetro.org/conference-paper/SPE-189471-MS

-

Journal of Natural Gas Science and Engineering, Volume 51, March 2018, 104-115 2018

Experimental and statistical investigation of drilling fluids loss in porous media-part1

Dynamic fluid invasion experiments were conducted using the M2200 drilling simulator.

https://www.sciencedirect.com/science/article/abs/pii/S1875510017304948

-

Journal of Petroleum Science and Engineering, December 2018, Volume 171, 1326-1337 2018

Lost circulation and filter cake evolution: Impact of dynamic wellbore conditions and wellbore strengthening implications

Dynamic fluid invasion experiments were conducted using the M2200 drilling simulator.

https://www.sciencedirect.com/science/article/abs/pii/S0920410518307290

-

OMAE2018-78722 2018

Qualification of Multiple Factors and Interaction Effects on Drilling Fluid Invasion

The dynamic drilling fluid invasion experiments were carried out on the M2200 drilling simulator.

https://doi.org/10.1115/omae2018-78328

-

AADE-17-NTCE-094 2017

How does Rock Type and Lithology Affect Drilling Fluid’s Filtration and Plastering?

Highlight and justify the importance of lithology and rock type, on dynamic mud filtration and plastering. M2200 has been used to characterize dynamic drilling fluid filtration, for different lithologies, at specified experimental conditions.

Click here to download the PDF.

-

AADE-17-NTCE-100 2017

Evaluation of Measurement Techniques for Fluid Lubricity in the Laboratory

Perform a comprehensive study on measurement techniques to evaluate lubricants and the lubricity of drilling fluids. M2200 has been used to perform dynamic lubricity test under varied experimental conditions.

Click here to download the PDF.

-

Composition and Properties of Drilling and Completion Fluids (Seventh Edition), 55-91 2017

Chapter 3 – Evaluating Drilling Fluid Performance

Figure 3.15 M2200 HPHT lubricity, dynamic filtration, and drilling simulator

https://www.sciencedirect.com/science/article/pii/B9780128047514000031

-

International Scientific and Technical Conference 2017

Examination of Drilling Muds Lubricity on Contact with Borehole Wall under HPHT Conditions

The studies were conducted based on the measurement of the coefficient of friction using a Grace M2200 HPHT drilling simulator. The coefficient of friction was determined on steel-steel contact and steel-sandstone contact.

http://194.44.112.14/bitstream/123456789/5964/1/6564p.pdf

-

University of Leoben Master Thesis 2017

Experimental Design to Investigate the Casing Smearing Effect

Lubricity, Filtration, Drilling Simulator – M2200: This apparatus features a temperature and pressure controlled work environment to simulate downhole conditions. The filter medium is available in different porosities and permeabilities. A shear bob can simulate the rotation of the drill string concentric or off-center. This produces a certain shear rate on the filter cake. In an optional version, there is even a mud circulation system applied but only for lower pressures and temperatures. The main advantage of this apparatus is that it can rotate a shear bob off-center, which is exactly what happens during CwD. Nevertheless, it is important to find out if the rotation is simply off-center or if it performs a similar motion as during CwD. This would mean regular contact with the filter medium during rotation. If so, this would be the only apparatus which could simulate CwD conditions realistically so far.

https://pure.unileoben.ac.at/portal/files/1862343/AC13686645n01vt.pdf

-

ARMA 15-82 2015

American Rock Mechanics Association

An Integrated Analytical Workflow for Analyzing Wellbore Stress, Stability and Strengthening

Present an integrated and analytical workflow, such as performing an integrated mud loss volume prediction based on different mechanism. M2200 has been used to do filtration test and generate mud cake for property test.

https://www.onepetro.org/conference-paper/ARMA-2015-082