Foam Rheometer

M9200 HP/HT Foam Loop Rheometer

M9200 HP/HT Foam Loop Rheometer

M9200 HP/HT Foam Loop Rheometer

M9200 HP/HT Foam Loop Rheometer

M9200 HP/HT Foam Loop Rheometer

M9200 HP/HT Foam Loop Rheometer

M9200 HP/HT Foam Loop Rheometer

M9200 HP/HT Foam Loop Rheometer

M9200 HP/HT Foam Loop Rheometer

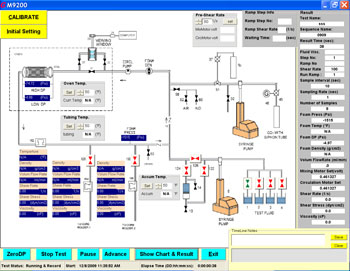

M9200 Core Flow™ PC Software

M9200 Core Flow™ PC Software

- Height: Custom

- Width: Custom

- Depth: Custom

- Weight: Custom

- The 9000 series products are all customizable.

Highest pressure and temperature rating of any foam rheometer in the world

Today's researchers must come to grips with some of the

harshest environments on earth, and the M9200 HPHT Foam Rheometer hardware is intended to address their needs by providing a test environment that is more robust and realistic than any competing instrument available today can provide.

M9200 provides dynamic foam circulation condition

instead of static condition, which results in foam

separation. This unique feature of M9200 enables

foam to be constantly circulated and sheared in the

loop for achieving uniform foam properties during

testing.

The integrated heat trace maintains a uniform temperature on all sample lines, further ensuring accurate test results.

The Grace Instrument M9200 HPHT Foam Rheometer is designed to simulate foam fracturing and acidizing processes under down hole conditions of temperature and pressure, while providing comprehensive data collection, including power law n' and k' values for future modeling. The M9200 computer-controlled automation package allows precise monitoring and variable flow-rate control.

| Dimensions: Custom (depending on client's desired specifications) |

| Weight: Custom (depending on client's desired specifications) |

| Operating Temperature: Ambient to 350°F |

| Working Pressure: Atm to 5,000 psi |

| Shear Rate: 0 to 1,500 S-1 |

| Sample Volume: 115 ml |

| Accumulator: 500 ml capacity, 6,000 psi |

| Viewing Cell: Stereo microscope • Sapphire window |

| Dual Gas: CO2 or N2 gas injection for foam creation |

| PC (Included): Desktop PC with MS Win 8.1, M9200 PC software preinstalled. |

- Single or dual gas (CO2 and/or N2) foam testing capability.

- Continuous foam circulation ensures uniform foam properties.

- Constant foam circulation and shear.

- HPHT viewing cell allows testing of acid samples and ensures safe operation.

- Visual determination of foam half life and digital measurement of bubble size and distribution.

- Integrated heating trace ensures that all lines are subjected to a uniform temperature.

- Accumulator for testing high viscosity and/or corrosive samples.

- Viewing cell images can be digitized and processed digitally.

- Designed to handle fluids and gases at temperatures up to 350°F, under a working pressure up to 5,000 psi.

Downloads for the M9200 HP/HT Foam Loop Rheometer:

Read more about our instrument's technical applications within these scientific and academic publications:

-

Cellulose 2017

The effect of PVA foaming characteristics on foam forming

Brookfield DV-II viscometer, Grace M9200 foam rheometer and assorted auxiliary devices were used to measure the surface viscosity for different PVA solutions at the surfactant concentration of 0.1 g/L.

http://dx.doi.org/10.1007/s10570-017-1452-1

-

SPE 160762 2012

Successful Application of Foamed Acid Stimulation on a Severely Perforation Damaged Horizontal Well with Perforations Behind Tubing

W. Ruksanor, J. Webers, E. Vargas, Sakhalin Energy Investment Company Ltd., R. Gdanski and S. Vickery, Shell International Exploration and Production

https://www.onepetro.org/conference-paper/SPE-160762-MS